OEM Custom Stainless Steel Oil Filtration Machines Sink

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 1000 Piece/Pieces |

| Transportation: | Ocean |

| Port: | Jiangmen,Shenzhen,Guangzhou |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 1000 Piece/Pieces |

| Transportation: | Ocean |

| Port: | Jiangmen,Shenzhen,Guangzhou |

Model No.: DJ-WIL-129

Brand: DONGJI

Place Of Origin: China

Size: Custom

Custom Package: Yes

Material: Stainless steel

Qualification: CE,UL, ISO, TUV

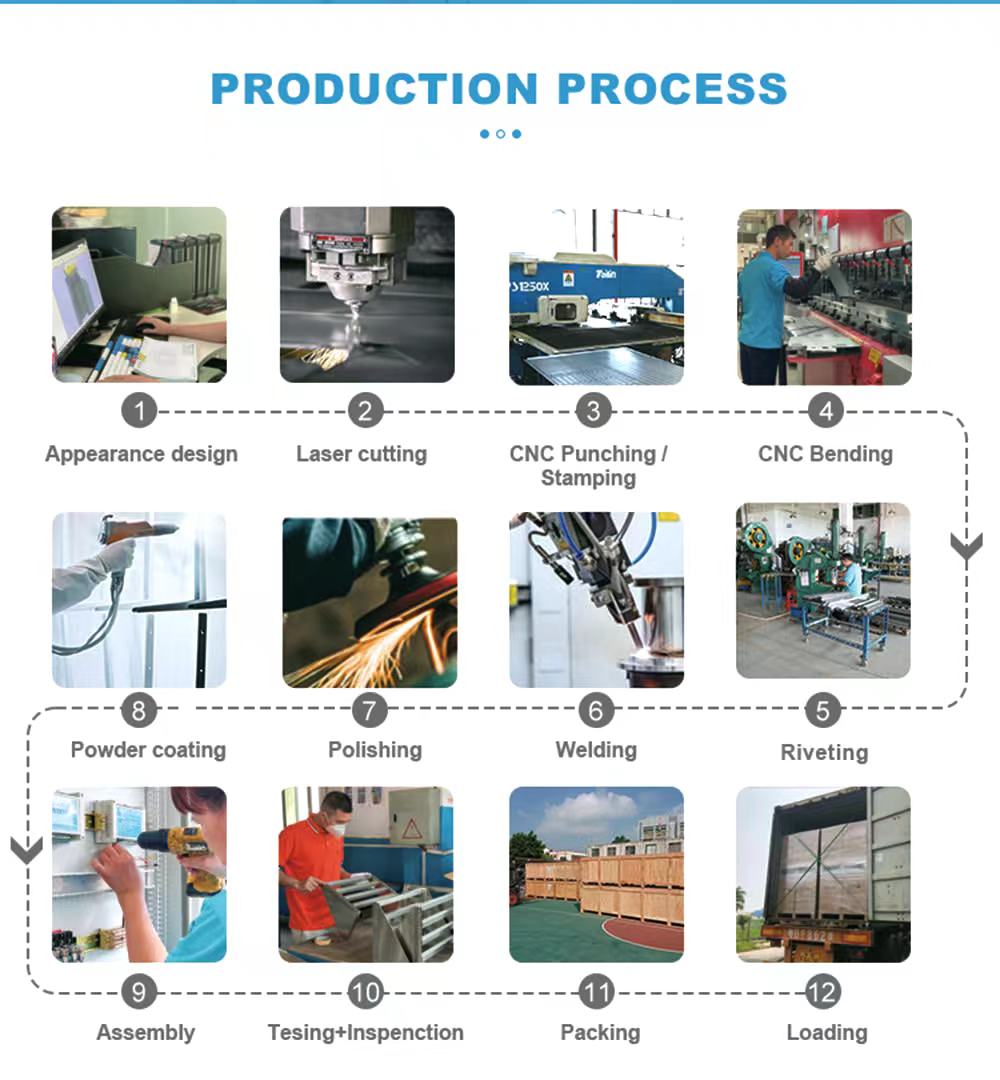

Craftmanship: Laser cutting, CNC punching, CNC bending, TIG welding, surface finishing,

Furface Finishing: 2B, Brushing, Polishing

Application: Fryer Oil Filtration Machines

| Selling Units | : | Piece/Pieces |

| Package Type | : | Custom or regular international delivery package |

Dongji has over 200 production staff, of which professional engineers account for about 25%, has more than 200 production patents, factory workshop of over 38,000 square meters and a whole set of sheet metal processing equipment. We specialize in manufacturing all kinds of OEM custom Stainless Steel Products, providing customers with from start to finish service. We can provide overall solution services according to customer demand, and reduce customer costs through overall services. Our grease filter sinks are durable, sturdy and beautiful.

Why you can trust us?

|

| ||||||||||||||||

| What can we do?

|  | ||||||||||||||||

|  |

Q1. What if the custom OEM stainless steel sinks are broken when we receive them?

Our products are 100% inspection before delivery. We will fix the items at our cost if we are responsible for the broken issues.Q2. What should I do if the Stainless Steel Polishing effect can not meet my request?

Most of our metal sinks are customized. Including material, dimensions and other design. Of course we will give you some suggestions if you are not sure about the details.

Q3. How long should we take for a quotation?

We will quote you within 3 days after receiving detailed information (your 2D/3D drawings or samples.)

Q4. How about the lead time?

15 days for sample, 30 days for mass production.