Custom Metal Electrolysis Apartment Smart Locker Assembly

$5≥1000Piece/Pieces

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 1000 Piece/Pieces |

| Transportation: | Ocean |

| Port: | Jiangmen,Shenzhen,Guangzhou |

$5≥1000Piece/Pieces

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 1000 Piece/Pieces |

| Transportation: | Ocean |

| Port: | Jiangmen,Shenzhen,Guangzhou |

Model No.: DJ-WIL-094

Place Of Origin: China

Size: Custom

Custom Package: Yes

Material: Cold roll steel

Application: Outdoor parcel locker

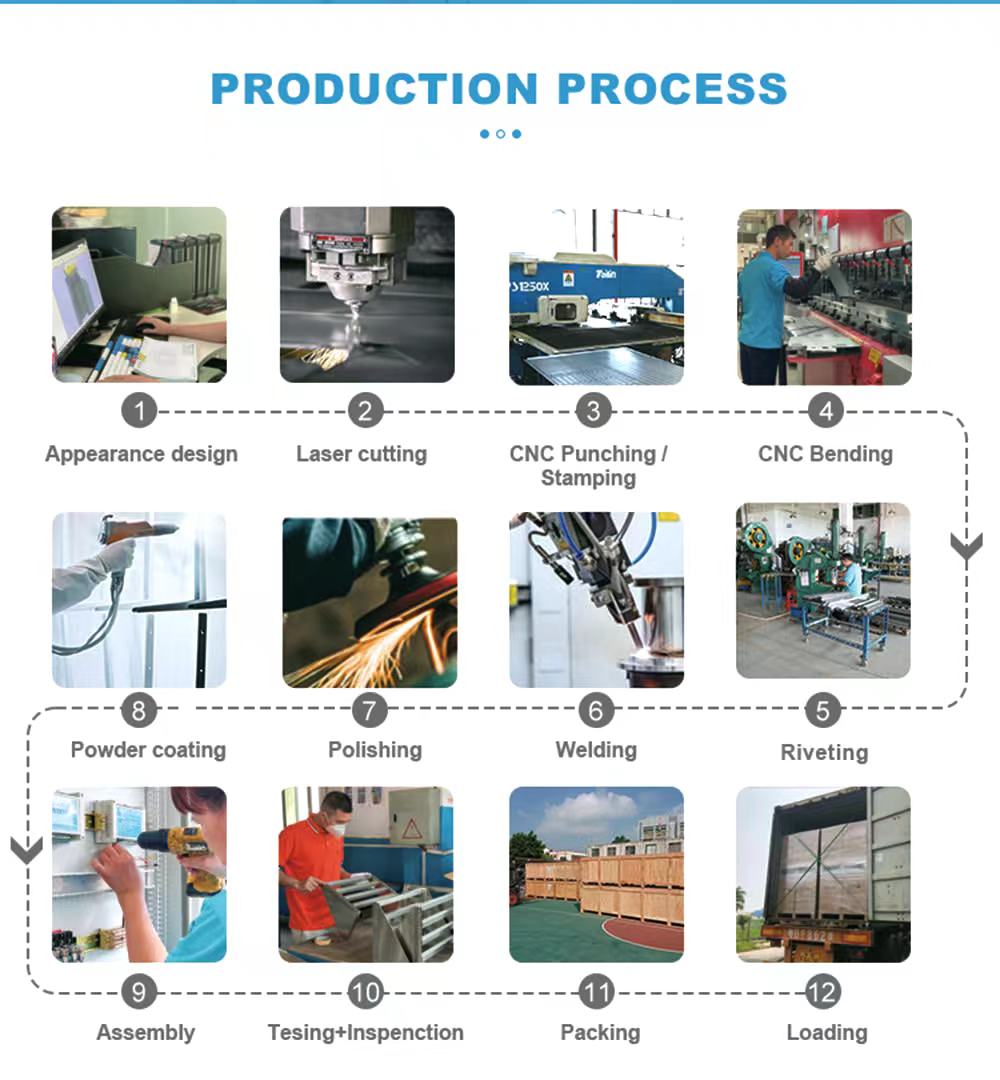

Craftmanship: Laser cutting, CNC punching, CNC bending, Carbon Dioxide welding, surface finishing, assembly

Qualification: CE,UL, ISO, TUV

Furface Finishing: Metal electrolysis

| Selling Units | : | Piece/Pieces |

| Package Type | : | Custom or regular international delivery package |

Custom Metal Electrolysis Apartment Smart Locker Assembly

Electropolishing results in changes in shape, structure, alloy composition, purity and energy state. During the completion of the fabrication process, the resulting surfaces are often very different in structure and properties, and in most cases the opposite of the substrate material. Surfaces used in systems requiring high purity depend on two properties: the surface itself should not transfer any species to the contact medium. The surface cannot have external impurities attached, and the surface cannot react with the surrounding medium. The first property is called the internal cause of surface purity, and the second is called the external cause.

The purity of the surface is mainly determined by corrosion resistance, particle precipitation and diffusion characteristics. For corrosion-resistant steels, these properties are primarily determined by the condition of the underlying material and can be greatly enhanced by electropolishing. For external purity, the adhesion and cleaning of stainless steel machined surfaces also has its passivation, and its catalytic behavior is mainly determined by the surface energy state and microstructure. Both properties can be directly affected by electropolishing. These damaged surfaces can be removed by electropolishing without greater pressure to a certain depth, and the material remains in its impure, free, original shape. Therefore, in a single process, the surface properties can be improved to a certain extent, which cannot be achieved by any other process.

The surface structure of Stainless Steel Machining is mainly based on the microscopic changes caused by electrolytic polishing. Both coarse and fine cracks in the structure are ground and removed. At the same roughness value, the electropolished surface is reduced by 80% and the surface area is reduced by about 10% compared to the stainless steel machined surface. Although the surface is smooth and dense from a microscopic point of view, there are some residual ripples on the surface according to the macroscopic conditions. At the same time, it does not burn, the proportion of pressed iron, the proportion of folding and the oxidation of matter. Internal purity, mechanical surface embedding depth up to a few microns. These inclusions can only be removed by electropolishing to destroy the layer of contaminated material and effectively remove them.

Established in 2021, Dongji has been focusing on the production of sheet metal products for many years. The smart parcel locker is one of our most-experienced products. We not only have laser Stainless Steel Cutting, CNC Stainless Steel Stamping, CNC Stainless Steel Bending, TIG Welding and other sets of equipment, but also have professional assembly workshop and Surface Finishing workshop.

Customized SPCC apartment parcel locker characteristics:

Why you can trust us?

|

| ||||||||||||||||

| What can we do?

|  | ||||||||||||||||

|  |

Q2. What should I do if the Metal electrolysis surface can not meet my request?

Most of our Metal electrolysis items are customized. Including material, dimensions and other design. Of course we will give you some suggestions if you are not sure about the details.

Q3. How long should we take for a quotation?

We will quote you within 3 days after receiving detailed information (your 2D/3D drawings or samples.)

Q4. How about the lead time?

15 days for sample, 30 days for mass production.