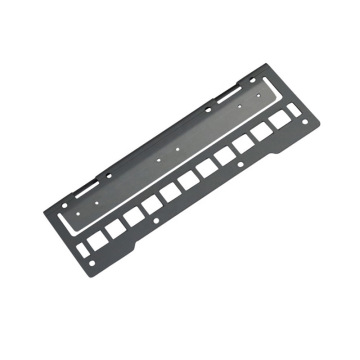

OEM Customized Galvanized Steel Cutting For Decoration Clock

Weld galvanized steel with the same preparation as ordinary mild steel. The size of the treatment tank and the proximity of the zinc coating are important. For penetration, the groove size should be appropriate, generally 60~65°, for leaving a gap, usually 1.5~2.5 mm; zinc In order to reduce the penetration of the weld, before welding, it can be galvanized after the braze layer of the groove , then remove.

In the actual supervision work, centralized chamfering and no blunt edge centralized control are adopted. The double layer welding process and the retail sale of galvanized square pipe reduce the possibility of incomplete penetration. The electrode should be selected according to the base material of the galvanized pipe. J422 is more common due to the ease of handling of mild steel.

Welding technology: When multi-layer welding is made of layers of weld bead, and the molten zinc coating can be evaporated, the evaporation escape can greatly reduce the liquid residue in the welding zinc. When fillet welding is performed, the zinc layer is preferably melted and evaporated in the layer, and then escapes from the weld. The method is to move the electrode end forward about 5-7mm, and after the zinc layer is melted, return to the original hot-dip galvanized steel pipe manufacturer in Jiangsu Province to continue welding. If cross welds and perpendicular welds are used, the tendency to undercut will be very small. Defect-free weld quality can be achieved if the back-and-forth strip technique is used.

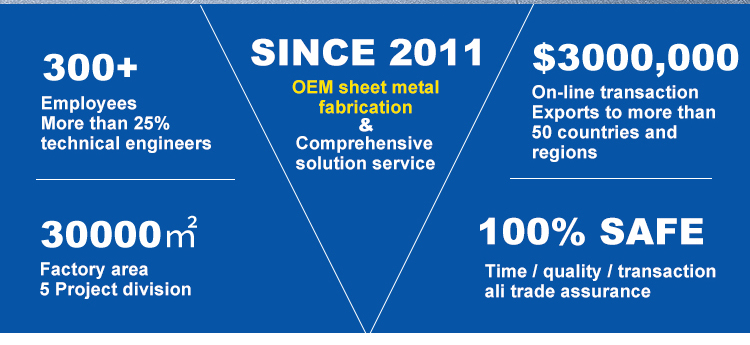

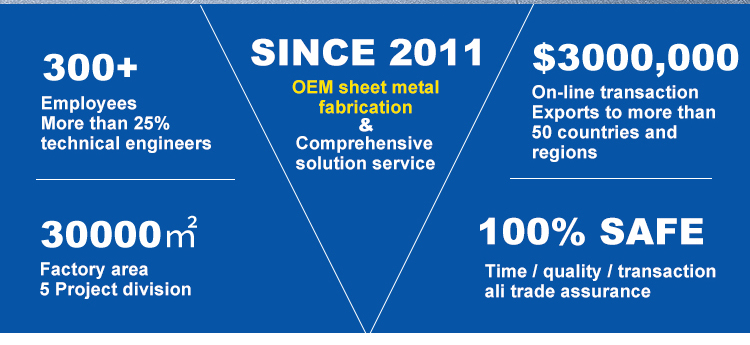

Our service and our main products

Our services include laser cutting, CNC Punching, Metal Bending, steel welding, stainless steel automatic welding line, shell foaming, surface powder coating, assembly, testing, etc.

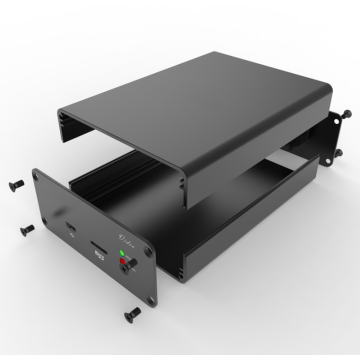

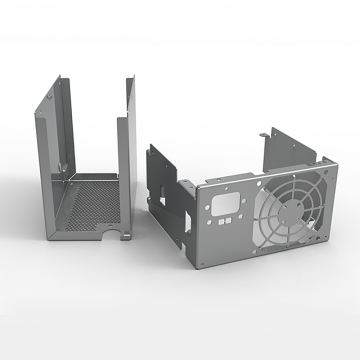

Our main product is customised Sheet Metal Fabrication and we can produce different kinds of sheet metal products - Metal Enclosures, metal cabinets, metal housings - according to customers' drawings.

We provide OEM one-stop sheet metal solutions.

DONGJI is professional in customized galvanized Steel Cutting fabrication for different kinds of decoration clocks.

As we all know, the function of galvanized steel plate is to protect the carbon steel inside by galvanizing the surface, and it is a kind of plate that is not easy to rust after long-term use.

OEM orders are welcome, we could support you high standard quality and compectitive price.

Products Description

Materials used:

* Aluminium, steel, stainless steel 201 or 304, galvanised, copper

* Material thicknesses ranging from 0.2mm-30mm depending on the material

* Some materials are RoHS compliant

* Material certification on request

Polishing:

* Powder coating, painting, electroplating, anodising, polishing, sandblasting, etc.

Custom sheet metal designs welcome!

Fabricaition Service

FAQ

Q1: Are you a sheet metal fabrication Comprehensive service provider?

We are an ISO 9001 certified factory specialized in sheet metal fabrication Comprehensive service provider.

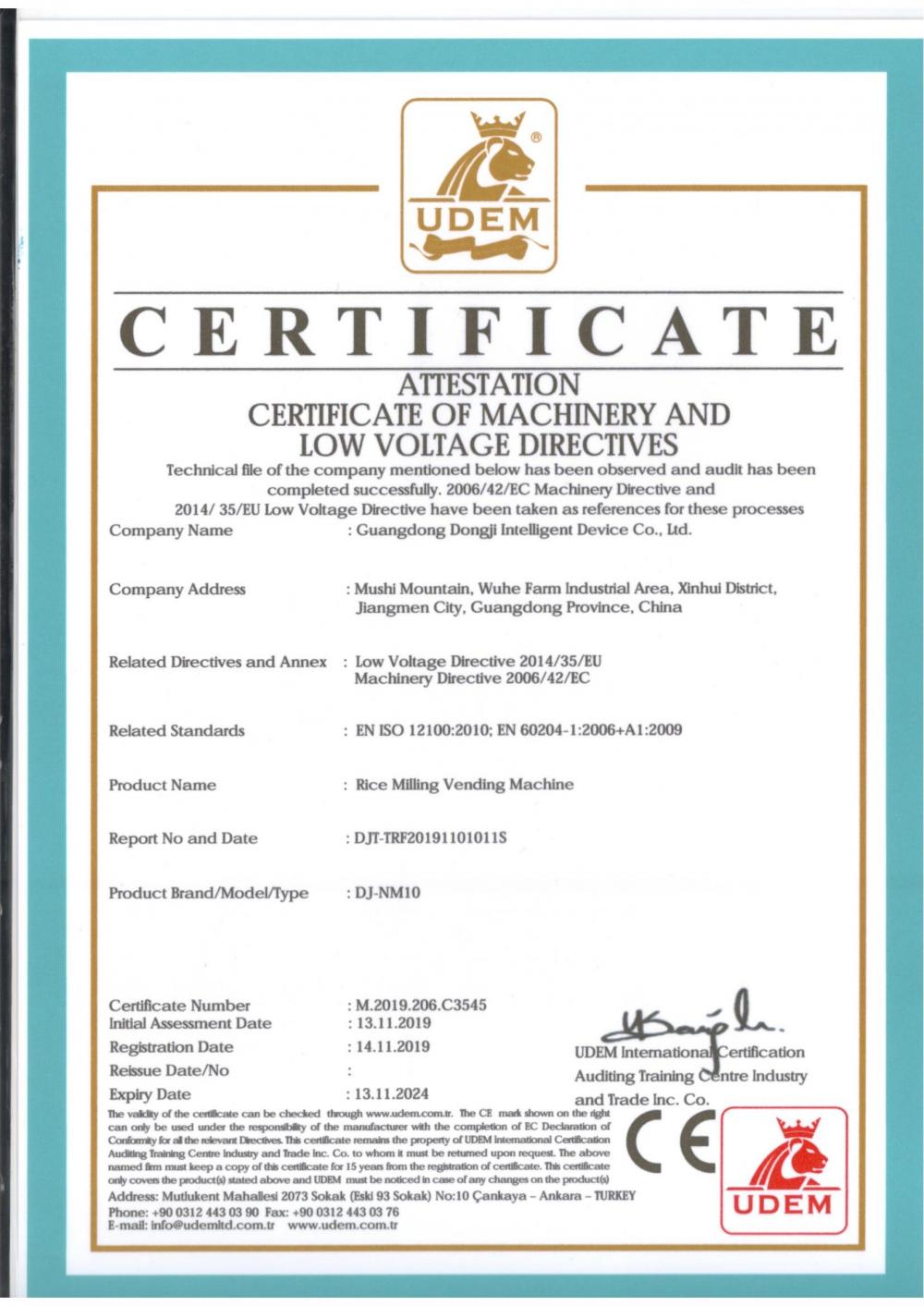

Q2: Does Dongji have any certifications?

We have ISO 9001: 2017 and UL Certifications.

Q3: What services does DongJi offer?

Our services include sheet metal product laser cutting, punching, bending, welding, stamping, finishing, assembly, testing and so on.

We have experience in work fabrication for a variety of metals such as Stainless Steel, Aluminum, carbon Steel, Cold Rolled Steel, High Carbon Steel, Hot Rolled Steel.

Q4: Does Dongji provide design and engineering?

DongJi specializes in design and engineering. We can work with you from start to finish on any product you are creating.

Q5: Can Dongji assist to do assemble and testing for products?

Dongji can assist you in assembling any type of product. We have 11 years of experience in R&D, production assembly and testing of smart devices. Our engineering R&D team includes electronic engineers, circuit control engineers, software engineers, test engineers, etc.

We are confident that we can assist you with the assembly and testing of any project.

Q6: How long should we take for a quotation?

After receiving detailed information (your 2D/3D drawings or samples), we will quote you within 3 days.

Q7: How about the lead time?

General speaking, 15 days for sample, 30 days for mass production. If you have any request, please contact with us.

Welcome to sent us your design so that we can quote you the price base on your design.

Contact: Carmen Huang