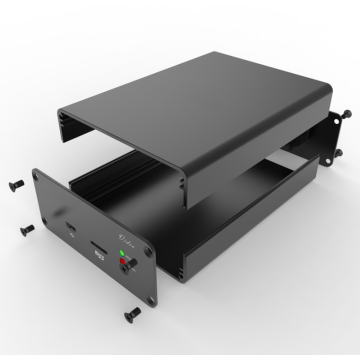

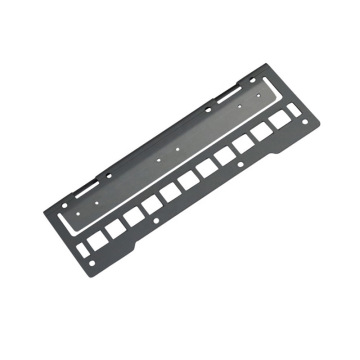

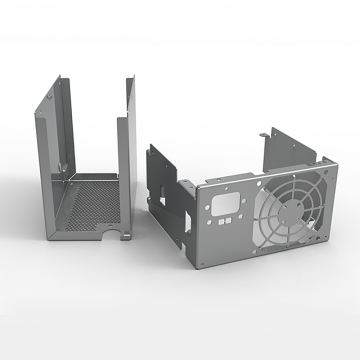

OEM Custom Galvanized Steel Rice Milling Machine Enclosure

Hot-dip galvanized steel is generally covered with a layer of zinc on low-carbon steel, and the galvanized layer is generally 20um thick. The melting point of zinc is exactly 419°C and the boiling point is about 908°C. Therefore, during the welding process, the zinc melt will float on the surface of the molten pool or the welding position. Zinc is a substance that has a high solubility in iron. The zinc etchant can also weld along the metal grain boundaries, and the melting point of zinc is low, resulting in "liquid metal embrittlement".

At the same time, zinc and iron can be formed by brittle intermetallic compounds, reducing the ductility and cracking of the weld metal under tensile stress. Fillet welds, especially T-joints, are prone to penetration cracks. During the welding of galvanized steel, the zinc layer on the surface of the groove and the edge will be oxidized, melted and evaporated due to the heat of the arc, and may even generate white smoke and steam, which is easy to produce welding pores.

The melting point of ZnO formed by oxidation is high. If the parameters are too small in the welding process, it will lead to slag inclusion in ZnO, and at the same time. Because zinc becomes a deoxidizer. FeO-MnO or low melting point oxide slag is produced. Secondly, due to the evaporation of zinc, a large amount of white smoke volatiles are produced, which have harmful effects on the human body, so the welded galvanized layer must be polished.

Our service and our main products

1.Our service including laser cutting, CNC punch press, Metal Bending, steel welding, stainless steel automatic welding line, enclosure foaming, surface powder coating spraying ,assembly ,testing and so on.

2.Our main products are in customized Sheet Metal Fabrication, which can make different kinds of sheet metal products-Metal Enclosures, metal cabinets,metal housings as per customers' drawing.

3.OEM one stop sheet metal solution are Provided.

Dongji is a manufacturer of integrated sheet metal and assembly solutions for more than 12 years. We are not only a sheet metal manufacturer, but also a sheet metal manufacturer who can bring technical support and solutions to our customers. We could support our customer one-stop service: sheet metal fabrication+ assembly+ test.

Products Description

Materials used:

* Aluminum, Steel, Stainless Steel 201 or 304, Zinc-plated, Copper

* Material thickness range is 0.2mm-30mm, depending on the material

* RoHS compliance for certain materials

*Material certification can be provided according to customer requirements

Finishing:

* Powder coating, painting, electroplating, anodizing, polishing, sandblasting, etc. Welcome to custom sheet metal design!

Fabricaition Service

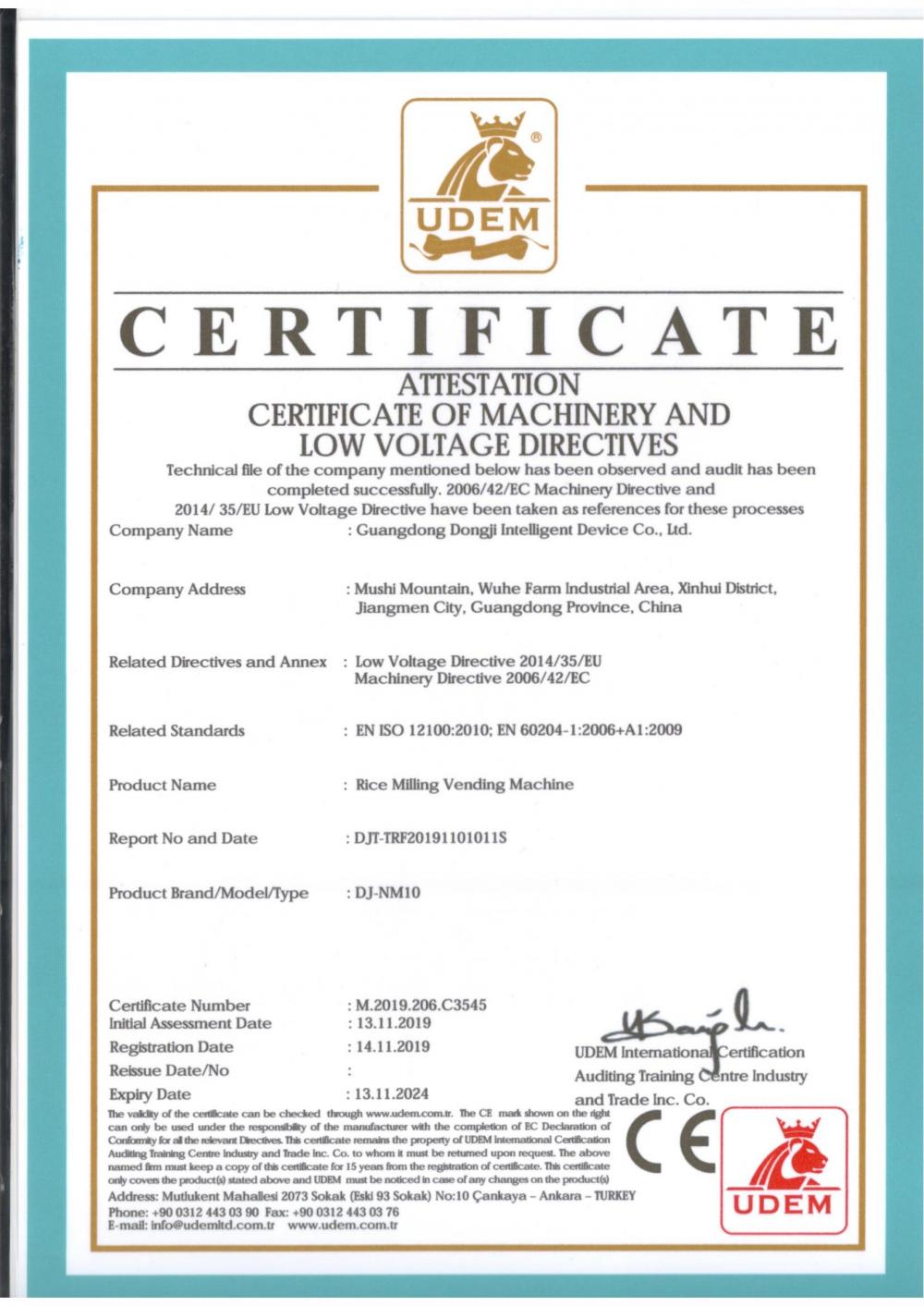

Our Certificates & Our Partner

FAQ

Q1: Are you a sheet metal fabrication Comprehensive service provider?

We are an ISO 9001 certified factory specialized in sheet metal fabrication Comprehensive service provider.

Q2: Does Dongji have any certifications?

We have ISO 9001: 2017 and UL Certifications.

Q3: What services does DongJi offer?

Our services include sheet metal product laser cutting, punching, bending, welding, stamping, finishing, assembly, testing and so on.

We have experience in work fabrication for a variety of metals such as Stainless Steel, Aluminum, carbon Steel, Cold Rolled Steel, High Carbon Steel, Hot Rolled Steel.

Q4: Does Dongji provide design and engineering?

DongJi specializes in design and engineering. We can work with you from start to finish on any product you are creating.

Q5: Can Dongji assist to do assemble and testing for products?

Dongji can assist you in assembling any type of product. We have 11 years of experience in R&D, production assembly and testing of smart devices. Our engineering R&D team includes electronic engineers, circuit control engineers, software engineers, test engineers, etc.

We are confident that we can assist you with the assembly and testing of any project.

Q6: How long should we take for a quotation?

After receiving detailed information (your 2D/3D drawings or samples), we will quote you within 3 days.

Q7: How about the lead time?

General speaking, 15 days for sample, 30 days for mass production. If you have any request, please contact with us.

Welcome to sent us your design so that we can quote you the price base on your design.

Contact: Carmen Huang